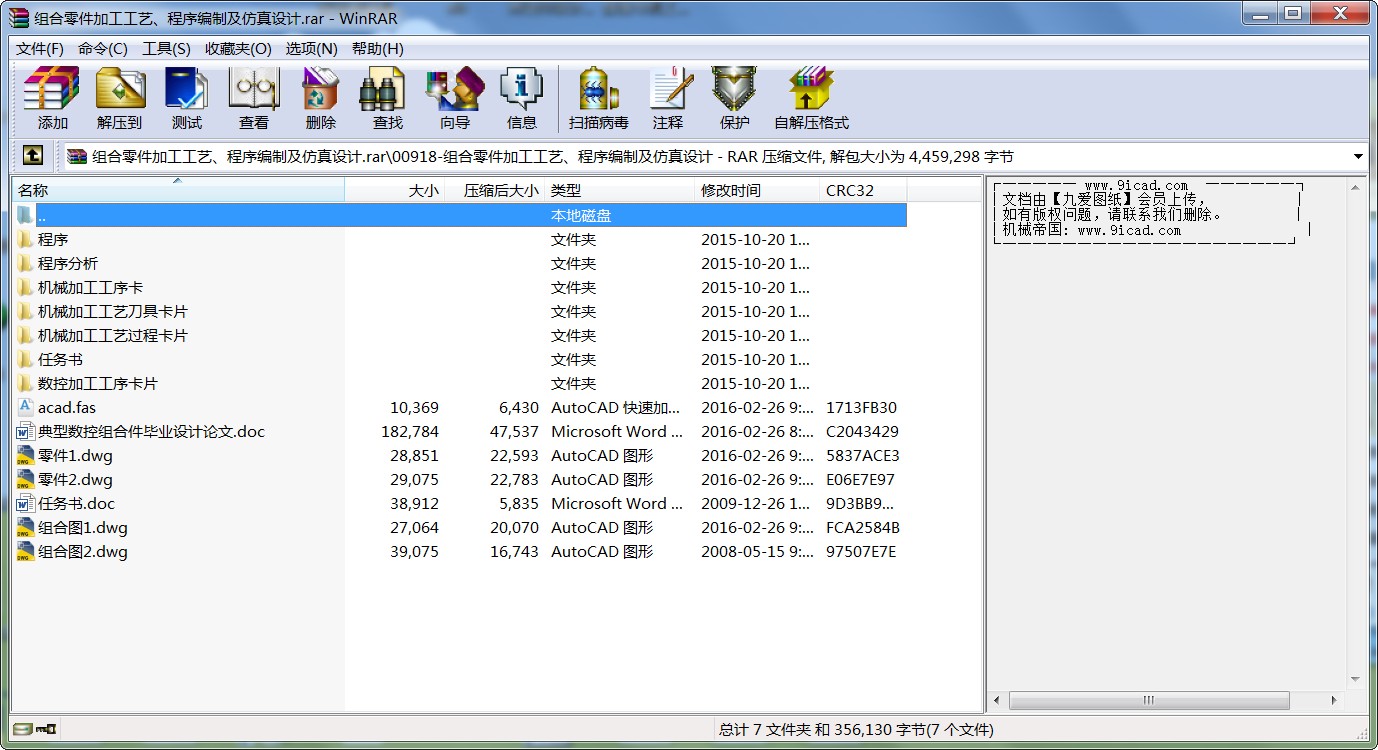

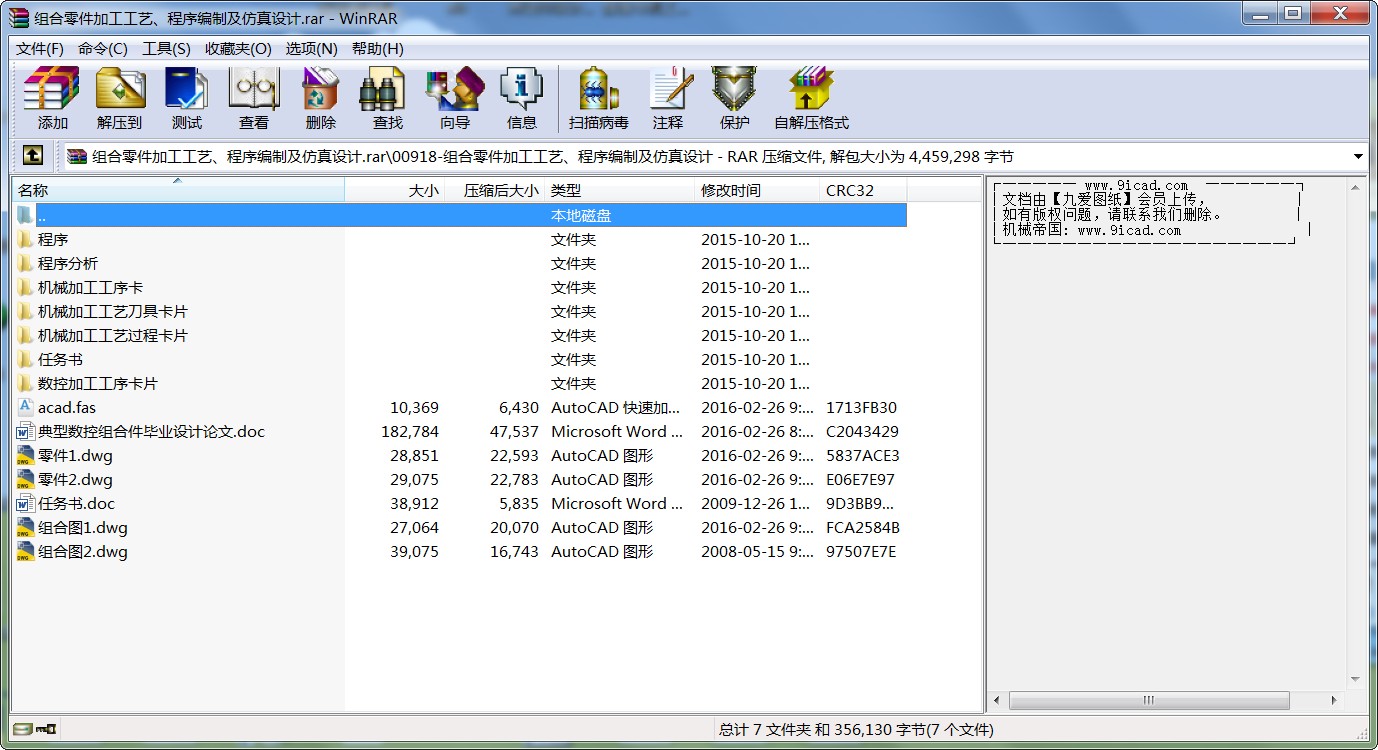

組合零件加工工藝、程序編制及仿真設(shè)計(jì)

- 文件介紹:

- 該文件為 rar 格式(源文件可編輯),下載需要

20 積分

-

- 組合零件加工工藝、程序編制及仿真設(shè)計(jì).rar

摘要

數(shù)控機(jī)床的組成部分包括測量系統(tǒng)、控制系統(tǒng)、伺服系統(tǒng)及開環(huán)或閉環(huán)系統(tǒng),在對數(shù)控零件進(jìn)行實(shí)際程序設(shè)計(jì)之前,了解各組成部分是重要的。

數(shù)控中,測量系統(tǒng)這一術(shù)語指的是機(jī)床將一個(gè)零件從基準(zhǔn)點(diǎn)移動(dòng)到目標(biāo)點(diǎn)的方法。目標(biāo)點(diǎn)可以是鉆一個(gè)孔、銑一個(gè)槽或其它加工操作的一個(gè)確定的位置。用于數(shù)控機(jī)床的兩種測量系統(tǒng)是絕對測量系統(tǒng)和增量測量系統(tǒng)。絕對測量系統(tǒng)(亦稱坐標(biāo)測量系統(tǒng))采用固定基準(zhǔn)點(diǎn)(原點(diǎn)),所有位置信息正是以這一點(diǎn)基準(zhǔn)。換句話說,必須給出一個(gè)零件運(yùn)動(dòng)的所有位置相對于原始固定基準(zhǔn)點(diǎn)的尺寸關(guān)系。X和Y兩維絕對測量系統(tǒng),每維都以原點(diǎn)為基準(zhǔn)。增量測量系統(tǒng)有一個(gè)移動(dòng)的坐標(biāo)系統(tǒng)。運(yùn)用增量系統(tǒng)時(shí),零件每移動(dòng)一次,機(jī)床就建立一個(gè)新的原點(diǎn)(基準(zhǔn)點(diǎn))。使用增量測量系統(tǒng)時(shí)的X和Y值。注意,使用這個(gè)系統(tǒng)時(shí),每個(gè)新的位置在X和Y軸上的值都是建立在前一個(gè)位置之上的。這種系統(tǒng)的缺陷是,如果產(chǎn)生的任何錯(cuò)誤沒有被發(fā)現(xiàn)與校正,則錯(cuò)誤會在整個(gè)過程中反復(fù)存在。

用于數(shù)控設(shè)備的控制系統(tǒng)通常有兩類,即點(diǎn)位控制系統(tǒng)和連續(xù)控制系統(tǒng)。點(diǎn)位控制數(shù)控系統(tǒng)機(jī)床(有時(shí)稱為位置控制系統(tǒng)數(shù)控機(jī)床)只有沿直線運(yùn)動(dòng)的能力。當(dāng)沿兩軸線以等值(X2.000,Y2.000)同時(shí)編程時(shí),會形成45度斜線。點(diǎn)位控制系統(tǒng)常用于需確定孔位的鉆床和需進(jìn)行直線銑削加工的銑床上,以一系列小步運(yùn)動(dòng)形成弧形和斜線。然而,用這種方法時(shí),實(shí)際加工軌跡與規(guī)定的切削軌跡略有不同。

Abstract

N/C machine tool elements consist of dimensioning system, servomechanisms and open- or closed-loop systems. It is important to understand each element prior to actual programming of a numerically controlled part.

The term measuring system in N/C refers to the method a machine tool uses to move a port from a reference point to a target point. A target point may be a certain location for drilling a hole, milling a slot, or other machining operation. The two measuring systems used on N/C machines are the absolute and incremental. The absolute (also called coordinate) measuring system uses a fixed reference point (origin). It is on this point that all positional information is based. In other words, all the locations to which a part will de moved must be given dimensions relating to that original fixed reference point. It shows an absolute measuring system with X and Y dimensions, each based on the origin. The incremental measuring system (also call delta) has a floating coordinating system. With the incremental system, the machine establishes a new origin or reference point each time the part is moved. It show X and Y values using an incremental measuring system. Notice that with this system, each new location bases its values in X and Y from the preceding location. One disadvantage to this system is that any errors made will be repeated throughout the entire program, if not detected and corrected.

There are two types of control systems commonly used on N/C equipment: point-to-point and continuous path. A point-to-point controlled N/C machine tool, sometimes referred to as a positioning control type, has the capability of moving only a straight line. However, when two axes are programmed simultaneously with equal values (X2.000 in., Y2.000 in.) a 45°angle will be generated. Point-to-point systems are generally found on drilling and simple milling machine where hole location and straight milling jobs are performed. Point-to-point systems can be utilized to generate arcs and angles by programming the machine to move in a series of small steps. Using this technique, however, the actual path machined is slightly different from the cutting path specified.

目 錄

第一章 概述

第二章 零件的數(shù)控加工工藝分析

1.機(jī)床的合理選用

2.數(shù)控加工零件工藝性分析

3.加工方法的選擇與加工方案的確定

4.工序與工步的劃分

5.輔助工序的安排及工序間的銜接

6.零件的安裝與夾具的選擇

7.刀具的選擇與切削用量的確定

8.對刀點(diǎn)與換刀點(diǎn)的確定

9.加工路線的確定

第三章 零件圖

第四章 零件加工工藝的分析

1.零件圖樣的工藝分析

2.確定裝夾方案

3.確定加工工序及進(jìn)給路線

4.選擇刀具

5.選擇切削用量

第五章 程序分析

第六章 程序

第七章 數(shù)控車床與普通車床的區(qū)別

第八章 數(shù)控車床的使用

第九章 總結(jié)

...