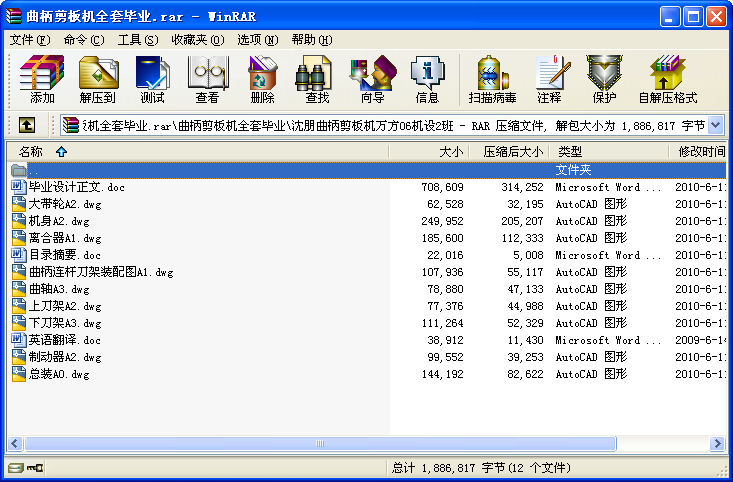

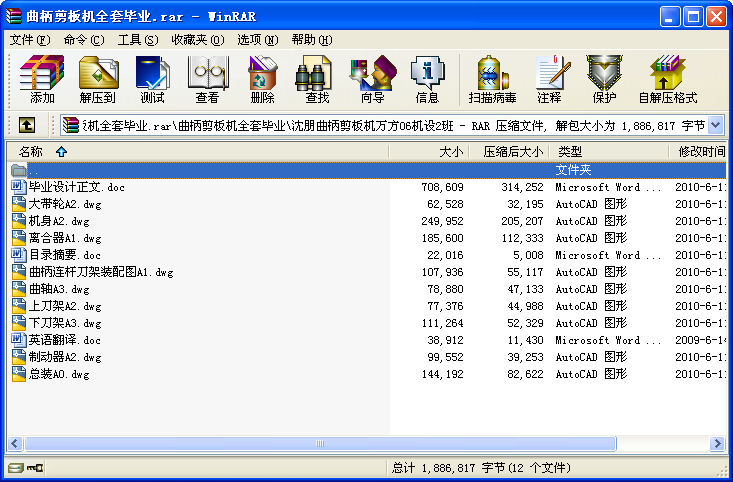

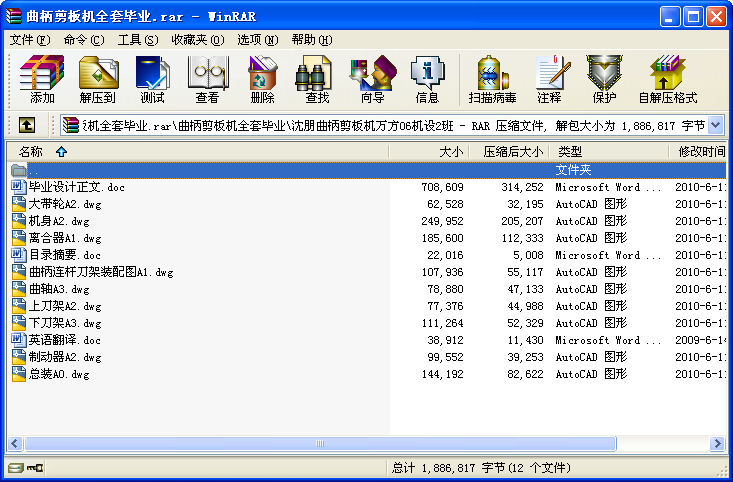

曲柄剪板機(jī)全套畢業(yè)設(shè)計(jì)

- 文件介紹:

- 該文件為 rar 格式(源文件可編輯),下載需要

20 積分

-

- 曲柄剪板機(jī)全套畢業(yè)

摘要

曲柄剪板機(jī)是通過(guò)曲柄滑塊機(jī)構(gòu)將電動(dòng)機(jī)的旋轉(zhuǎn)運(yùn)動(dòng)轉(zhuǎn)換為滑塊的直線往復(fù)運(yùn)動(dòng),對(duì)胚料進(jìn)行成型加工的鍛壓機(jī)械。曲柄剪板機(jī)動(dòng)作平穩(wěn),工作可靠,廣泛用于沖壓,擠壓。鍛模和粉末冶金等工藝。其結(jié)構(gòu)簡(jiǎn)單,操作方便,性能可靠。

關(guān)鍵詞:剪板機(jī),曲柄機(jī)構(gòu),機(jī)械制造

Abstract

Crank pressure machine is pass crank a slippery piece organization to revolve electric motor conversion for slippery piece of straight line back and forth sport, Carries the formed processing to the semifinished materials the forging and stamping machinery. The crank press movement is steady , the work is reliable, widely uses in crafts and so on ramming, extrusion, drop forging and powder metallurgy. Its structure is simple, the case of operation, the performance is reliable. The couping part uses the rigidity to transfer the key type coupling, the use service is convenient.

Key word : pressure machine, crank organization, machine manufacturing

Abstract

Crank pressure machine is pass crank a slippery piece organization to revolve electric motor conversion for slippery piece of straight line back and forth sport, Carries the formed processing to the semifinished materials the forging and stamping machinery. The crank press movement is steady , the work is reliable, widely uses in crafts and so on ramming, extrusion, drop forging and powder metallurgy. Its structure is simple, the case of operation, the performance is reliable. The couping part uses the rigidity to transfer the key type coupling, the use service is convenient.

Key word : pressure machine, crank organization, machine manufacturing

Abstract

Crank pressure machine is pass crank a slippery piece organization to revolve electric motor conversion for slippery piece of straight line back and forth sport, Carries the formed processing to the semifinished materials the forging and stamping machinery. The crank press movement is steady , the work is reliable, widely uses in crafts and so on ramming, extrusion, drop forging and powder metallurgy. Its structure is simple, the case of operation, the performance is reliable. The couping part uses the rigidity to transfer the key type coupling, the use service is convenient.

Key word : pressure machine, crank organization, machine manufacturing

目錄

前 言 1

第1章 緒論 3

1.1 剪板機(jī)械的概況和發(fā)展趨勢(shì) 3

1.2 剪切工藝的特點(diǎn)及對(duì)剪切機(jī)的要求 3

1.3 剪切原理 4

1.4 國(guó)內(nèi)的發(fā)展?fàn)顩r與差距 8

1.5 課題的主要內(nèi)容 9

第2章 擬定方案 10

2.1總體方案的確定 10

2.1.1 剪切機(jī)械介紹 10

2.1.2 機(jī)械結(jié)構(gòu)分析 11

2.1.3 剪扳機(jī)的方案陳述 14

2.1.4方案比較 18

2.2 曲柄剪板機(jī)傳動(dòng)設(shè)計(jì)方案 18

2.2.1 方案陳述 18

2.2.2 方案比較 19

2.3 剪板機(jī)的基本參數(shù) 20

第3章 曲柄連桿機(jī)構(gòu)設(shè)計(jì) 21

3.1 曲柄連桿機(jī)構(gòu) 21

3.2 曲軸設(shè)計(jì)計(jì)算 21

3.3 連桿機(jī)構(gòu) 24

3.4 曲軸連桿機(jī)構(gòu)中的滑動(dòng)軸承 24

3.5上刀架與床身導(dǎo)軌 25

第4章 離合器和制動(dòng)器 26

4.1 離合器的選用與計(jì)算 26

4.1.1離合器的結(jié)構(gòu) 26

4.1.2離合器的操縱機(jī)構(gòu) 26

4.1.3 轉(zhuǎn)鍵的材料與校核 27

4.2 制動(dòng)器的選擇與計(jì)算 28

第5章 電動(dòng)機(jī)的選擇與飛輪設(shè)計(jì) 32

及皮帶傳動(dòng)設(shè)計(jì) 30

5.1 電動(dòng)機(jī)的選擇 30

5.1.1一個(gè)工作循環(huán)所消耗的能量 30

5.1.2電動(dòng)機(jī)的選擇 31

5.2 飛輪轉(zhuǎn)動(dòng)慣量的計(jì)算 31

5.3皮帶傳動(dòng)設(shè)計(jì) 33

5.3.1 確定計(jì)算功率 33

5.3.2 選擇V帶型號(hào) 33

5.3.3 確定代的基準(zhǔn)直徑 33

5.3.4確定中心距和帶的基準(zhǔn)長(zhǎng)度 34

5.3.5確定V帶根數(shù) 34

第6章 機(jī)身設(shè)計(jì) 35

6.1 機(jī)身結(jié)構(gòu)及其主要尺寸 35

6.2 開式機(jī)身強(qiáng)度計(jì)算 36

6.3機(jī)身剛度校驗(yàn) 37

第7章 輔助裝置 40

7.1 壓料器 40

7.2 自動(dòng)送料裝置 41

結(jié) 論 43

致謝 45

參考文獻(xiàn) 46

...

熱門關(guān)鍵詞:

熱門關(guān)鍵詞:

豫公網(wǎng)安備 41072402000322號(hào)

豫公網(wǎng)安備 41072402000322號(hào)